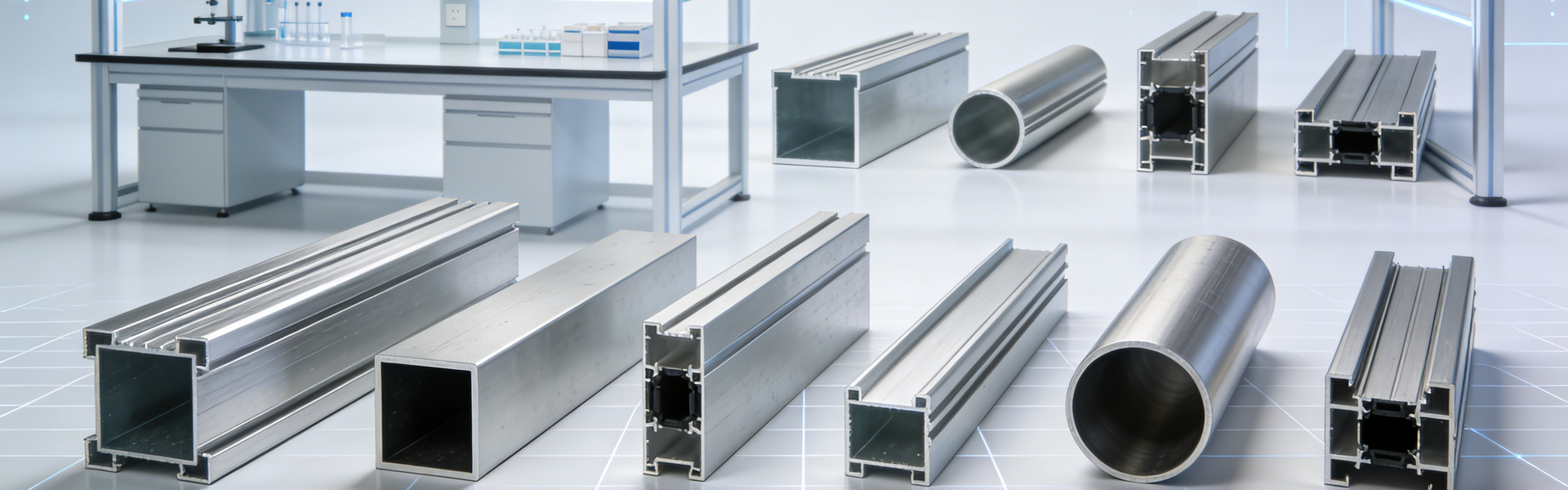

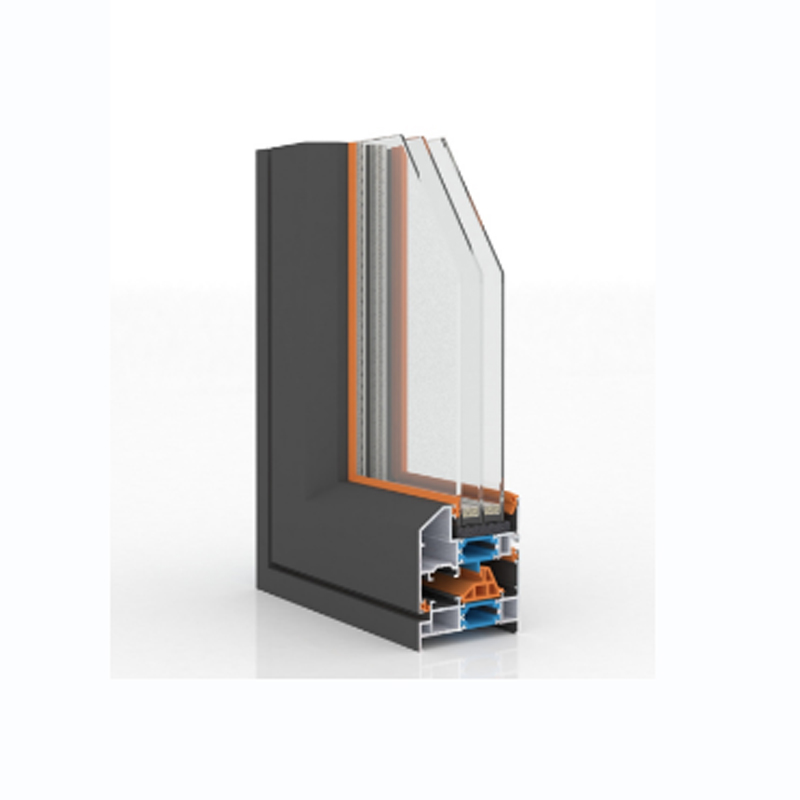

Thermal break technology is a fabrication method for aluminum doors and windows, which entails integrating an insulating barrier between the interior and exterior sections of the frame. Below are the key advantages of applying this technology to aluminum doors and windows.

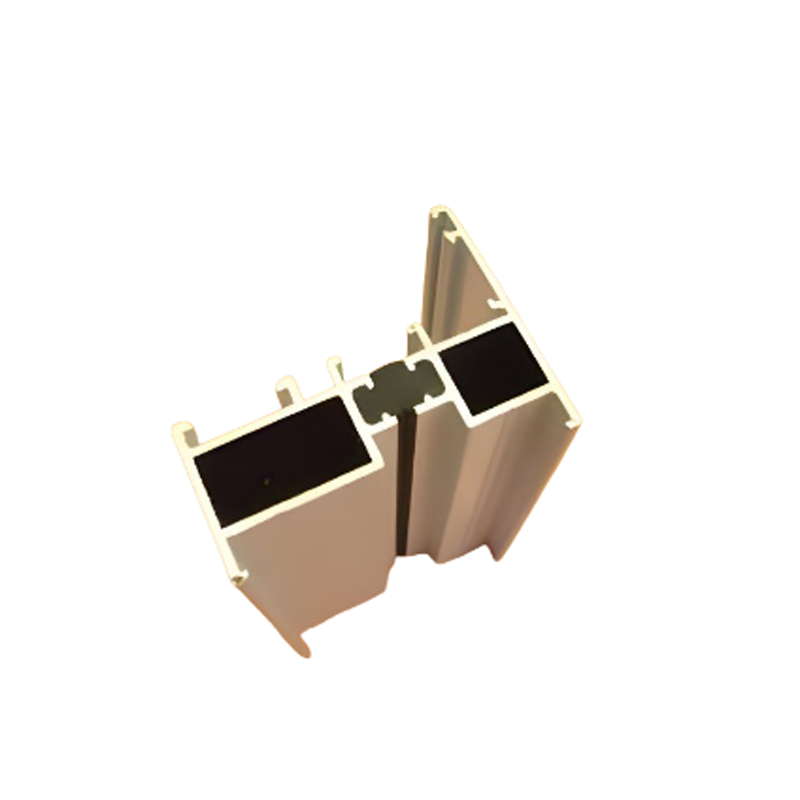

- 1. Thermal Bridge Disruption

The most fundamental feature is breaking the thermal bridge of the aluminum frame. It inserts low-thermal-conductivity insulating strips (typically PA66 GF25 nylon strips with glass fiber reinforcement) between the interior and exterior aluminum profiles, physically separating the two parts. This blocks the direct transfer of heat or cold between the indoor and outdoor environments, preventing heat loss in winter and heat penetration in summer.

- 2. Superior Energy Efficiency

By cutting off thermal conduction, the technology significantly reduces the energy consumption of heating and cooling systems. Doors and windows equipped with this technology can maintain a stable indoor temperature, lowering the overall energy costs of buildings. This feature makes it compliant with modern green building standards and energy-saving regulations.

- 3. Condensation Prevention

In humid climates or during temperature differences between indoor and outdoor, ordinary aluminum frames are prone to condensation due to temperature transfer. Thermal break structures keep the surface temperature of the interior aluminum profile close to the indoor temperature, effectively reducing or eliminating condensation on the frame, which helps avoid mold growth and wall moisture damage.

- 4. Enhanced Structural Stability

The insulating strips used in the technology have high mechanical strength and good durability. They not only play an insulating role but also connect the interior and exterior aluminum profiles firmly, ensuring the overall structural rigidity of the doors and windows. The profiles can still maintain stable performance under harsh conditions such as wind pressure and temperature changes.

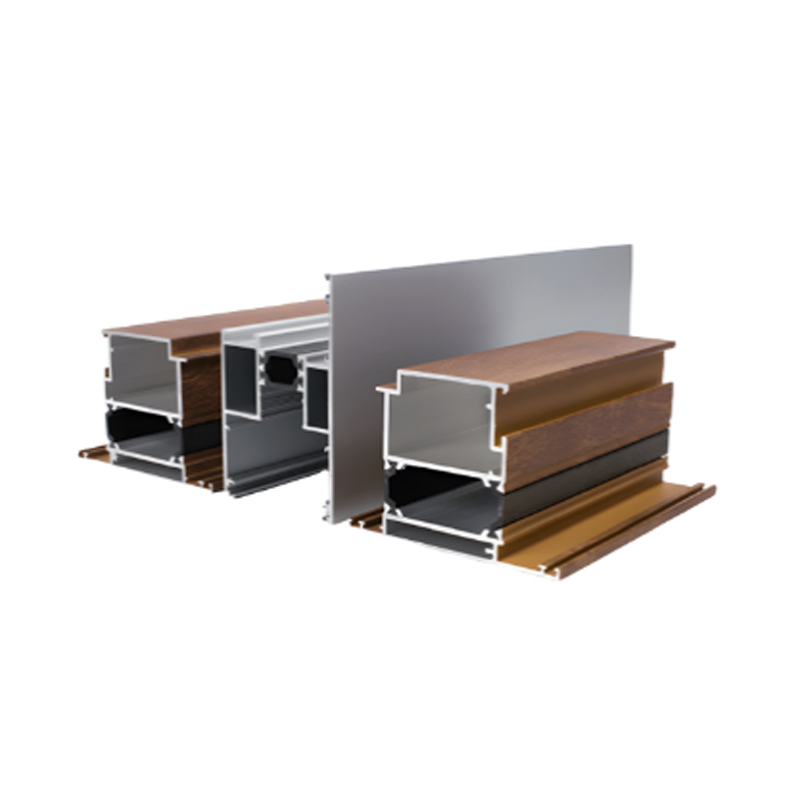

- 5. Compatible with Multi-functional Design

Thermal break aluminum profiles can be integrated with other functions, such as sound insulation seals, multi-chamber cavity designs, and hardware installation slots. This allows the doors and windows to achieve a combination of thermal insulation, sound insulation, waterproofing, and anti-theft performance, meeting the diversified needs of different building scenarios.