As a leading aluminum processing enterprise with decades of expertise, Kinbon Aluminum delivers high-performance, customized aluminum profile solutions tailored for the aluminum formwork industry—empowering construction projects with efficiency, durability, and cost-effectiveness.

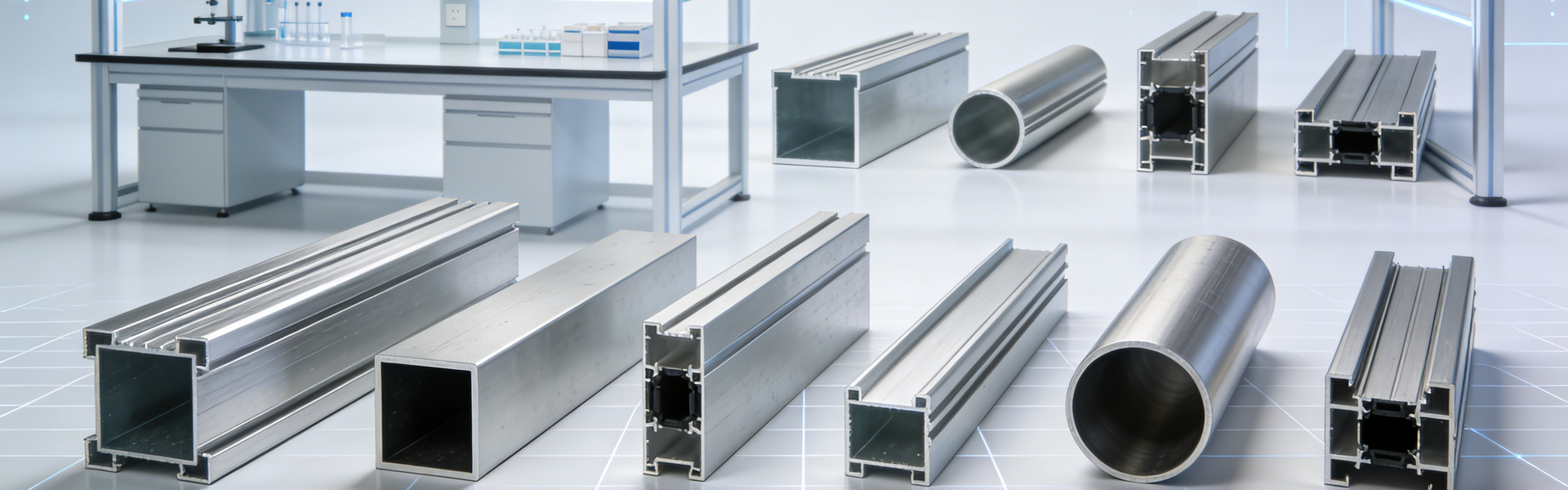

1.High-Quality Profile Materials

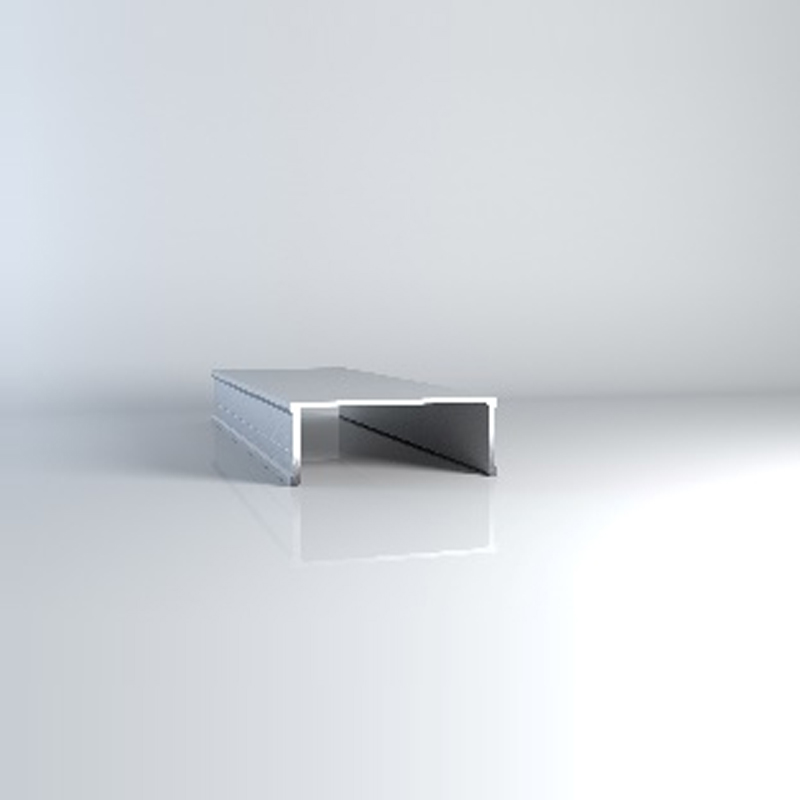

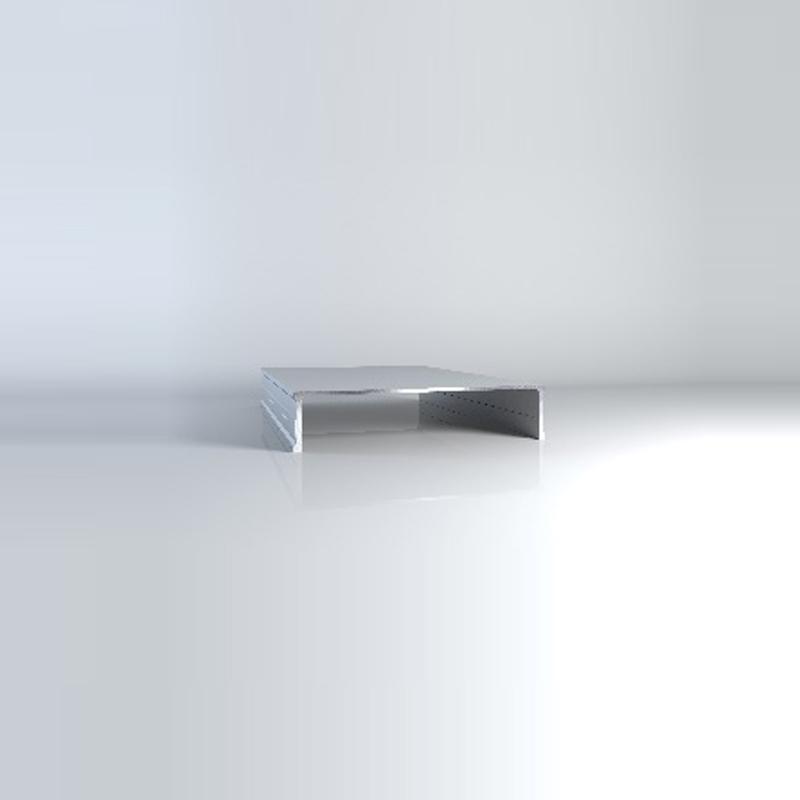

Our aluminum formwork profiles are extruded from 6061-T6/T5 high-strength aluminum alloy (compliant with GB/T 6892, ASTM B221 standards), featuring:

- 1.1Superior mechanical properties: Tensile strength ≥260MPa, yield strength ≥240MPa, ensuring load-bearing capacity (supports up to 60kN/m²) for high-rise building construction.

- 1.2Excellent corrosion resistance: Anodized surface treatment (thickness ≥10μm) or electrostatic powder coating, effectively resisting concrete alkalinity, moisture, and outdoor environmental erosion—extending the formwork’s service life to 300+ reuse cycles (far exceeding traditional steel or wood formwork).

- 1.3Lightweight design: Density of only 2.7g/cm³ (1/3 of steel), reducing on-site handling labor by 40% and lowering hoisting costs.

-

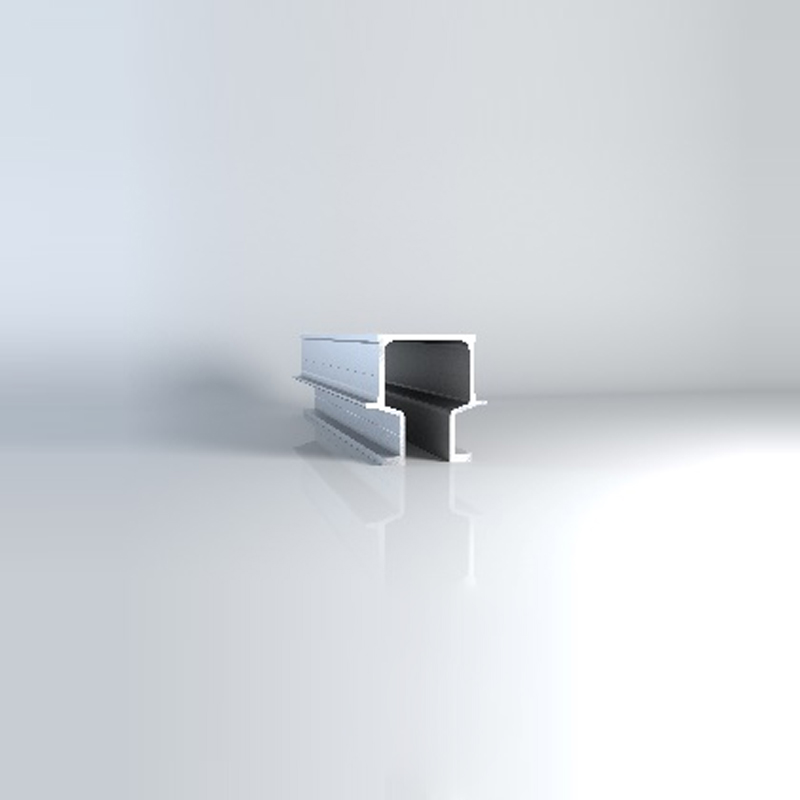

- 2.Customized Product Portfolio

To further empower customized aluminum formwork production, Kinbon is equipped with state-of-the-art manufacturing facilities—including friction stir welding (FSW) systems and a full range of punching machines—enabling one-stop, high-precision production of tailored formwork products that meet diverse project requirements.

- 2.1Friction Stir Welding (FSW): High-Strength, Seamless Joints for Formwork Assemblies

Our professional FSW equipment (with 3-axis/5-axis CNC control) is specifically optimized for aluminum formwork components, delivering unmatched joint performance:

- Superior joint quality: FSW creates defect-free, metallurgically bonded joints (no porosity, cracks, or thermal distortion) with tensile strength up to 90% of the base material (6061-T6 alloy), far exceeding traditional MIG/TIG welding. This ensures formwork structures maintain stability even under high load (e.g., concrete pouring pressure).

- Surface integrity: The welding process produces a smooth, flush joint surface (no spatter or post-weld grinding needed), which directly contributes to a high-quality concrete finish (reducing the need for post-construction polishing).

- Customized welding solutions: Capable of welding profiles with complex shapes (e.g., curved formwork panels, irregular corner assemblies) and variable thicknesses (3mm–12mm), supporting non-standard formwork designs for unique architectural structures (e.g., curved facades, special-shaped columns).

- 2.2Precision Punching Machines: Efficient, Accurate Hole Processing for Formwork Connections

Kinbon’s advanced punching equipment (CNC turret punches, hydraulic punches) enables high-precision hole fabrication for formwork connection systems:

- High accuracy & consistency: Punching tolerance is controlled within ±0.05mm, ensuring perfect alignment of connection holes (e.g., tie rod holes, clip mounting holes) across batch-produced formwork components. This eliminates on-site assembly errors and speeds up installation.

- Diverse hole types & sizes: Capable of processing round holes, slotted holes, square holes, and custom-shaped holes (1mm–50mm in diameter) on profiles of different cross-sections (e.g., main beams, vertical ribs). This flexibility supports compatibility with various formwork connection accessories (e.g., wedge clamps, lock pins).

- High efficiency: Our automated punching lines can process up to 120 holes per minute, enabling mass production of customized formwork components while maintaining strict delivery schedules (even for small-batch, highly customized orders).

- 3.Integrated Custom Formwork Production: From Design to Delivery

Combining FSW, punching, and our extrusion capabilities, Jinpeng offers end-to-end custom formwork production:

- 3.1Design collaboration: Our engineering team works with clients to finalize formwork drawings (incorporating hole positions, welding joints, and profile dimensions) based on project blueprints.

- 3.2Precision manufacturing: Extruded profiles are first processed via CNC punching (for connection holes), then assembled and welded using FSW (for structural joints)—ensuring each component meets exact design specifications.

- 3.3Quality inspection: 100% inspection of welded joints (via tensile testing, visual inspection) and punched holes (via coordinate measuring machines) to guarantee formwork performance and compatibility.