Рекомендуемые новости

Tianjin Jinpeng Aluminum Alloy Precision Manufacturing Co., Ltd.

Tianjin Jinpeng Aluminum Alloy Precision Manufacturing Co., Ltd. is located at the foot of Yanshan Mountain in Jizhou District, Tianjin, China. Covering an area of approximately 1.4 million squa…

Jinpeng Aluminum Participates in the China International (Tianjin) Doors and Windows Industry Partner Exchange Conference

Recently, the "China International (Tianjin) Doors and Windows Industry Partner Exchange Conference," jointly organized by the China Vision Blue Ocean Doors and Windows Curtain Wall Industry Developm…

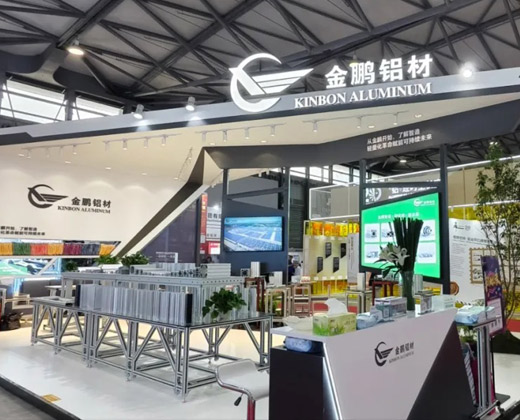

Successful Conclusion | Jinpeng Aluminum’s Highlights from the 2024 FBC China International Window and Curtain Wall Expo!

On October 19th, the four-day FBC China International Window and Curtain Wall Expo concluded successfully at the Shanghai National Exhibition and Convention Center. Jinpeng Aluminum showcased seve…

A perfect conclusion! | Jinpeng Aluminum’s highlights from the 2025 China International Aluminum Industry Exhibition

On July 11th, the three-day China International Aluminum Industry Exhibition successfully concluded! This exhibition brought together high-quality resources from the global aluminum industry and i…