Mould making

Jinpeng Aluminum boasts a world-class mould manufacturing setup, equipped with high-precision CNC mould machining centers, CNC wire-cut electrical discharge machines (WEDM-LS), and sinker electrical discharge machines (EDM). These advanced pieces of equipment are pivotal to achieving micron-level machining accuracy and elevating production efficiency across our entire mould-making process. Specifically, the CNC machining centers deliver rapid and precise milling, drilling, and shaping of mould cavities and cores; the WEDM-LS ensures ultra-fine cutting of complex mould contours with minimal thermal deformation; and the EDM enables the processing of hard-to-cut materials and intricate features that conventional machining methods cannot reach. Together, this integrated equipment lineup guarantees that every extrusion mould meets the strictest dimensional tolerances (within ±0.01mm for critical components), laying a solid foundation for the consistent quality of our aluminum profiles.

Complementing our cutting-edge hardware is a dedicated, industry-leading mould design team, spearheaded by a veteran senior engineer with over 20 years of specialized experience in aluminum extrusion mould technology. This team comprises professional designers, structural analysts, and process engineers who work in synergy to tackle diverse and complex project requirements. Leveraging advanced CAD/CAM/CAE software, they conduct precise finite element analysis (FEA) for mould stress distribution, simulate extrusion processes to optimize die structure, and customize mould solutions tailored to different aluminum alloy grades—including 6063, 6061, 6082, and even high-strength industrial alloys. Whether it is standard profiles with simple cross-sections, complex multi-cavity profiles for building systems, or customized special-shaped profiles for solar mounting, automotive, or electronic applications, the team can fully satisfy the production needs of all types of alloy components and profile cross-sections.

By integrating state-of-the-art manufacturing equipment with a highly experienced R&D and design team, Jinpeng Aluminum not only ensures the rapid delivery of high-quality moulds but also provides a robust, end-to-end technical guarantee for the stability, precision, and durability of our aluminum profile products. This technical advantage enables us to support clients with customized solutions efficiently and helps us maintain a leading position in the global aluminum extrusion industry.

With advanced production lines, Jinpeng can fabricate up to 100,000 sets of high-precision extrusion moulds annually.

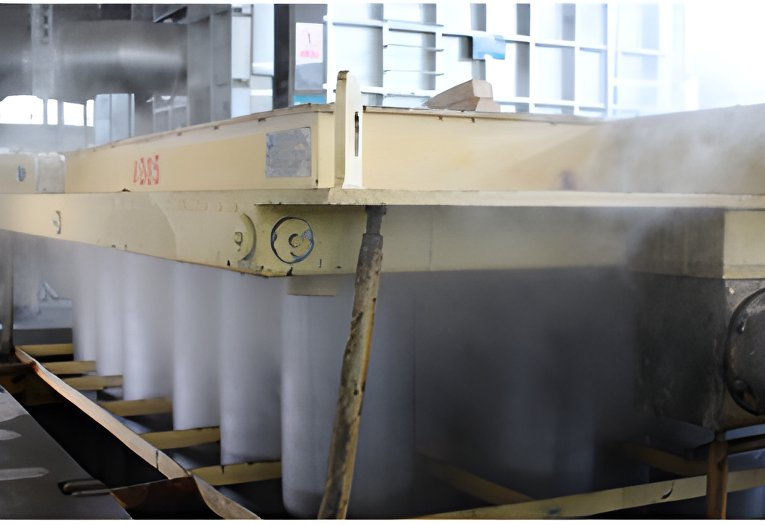

Aluminum Melting & Casting

We have integrated a suite of cutting-edge technologies into our production process, including internationally advanced regenerative combustion systems, online degassing systems, and electromagnetic stirring systems. Complementing these core facilities are state-of-the-art aluminum alloy billet homogenization systems and proprietary technologies sourced from both domestic and global industry leaders. This sophisticated technological configuration ensures that our 1xxx to 7xxx series aluminum alloy billets achieve unparalleled compositional uniformity and consistent mechanical performance. Specifically:

1. The regenerative combustion system maximizes thermal efficiency by recycling exhaust heat, cutting energy consumption by up to 30% while maintaining precise melting temperatures. This not only reduces carbon emissions but also prevents overheating-related alloy segregation, laying a solid foundation for high-quality billet production.

2. The online degassing system removes hydrogen and harmful impurities in real time during the molten aluminum treatment process. By injecting high-purity inert gas into the melt and utilizing rotor stirring, it effectively lowers the hydrogen content in the alloy to below 0.12 mL/100g Al, eliminating porosity defects in the final billets and enhancing their structural integrity.

3. The electromagnetic stirring system generates a stable rotating magnetic field to agitate the molten aluminum uniformly. This breaks up solidified alloy dendrites, promotes the uniform distribution of alloying elements (such as magnesium, silicon, and copper), and eliminates regional compositional differences in the melt.

4. The advanced homogenization system and technologies further refine the billet quality through controlled heating and insulation processes. This step eliminates internal stress in the cast billets, homogenizes the microstructure of the alloy, and improves the extrudability of the billets—critical for producing complex profiles with consistent mechanical properties across batches. Thanks to these integrated technologies, our 1xxx to 7xxx series aluminum alloy billets deliver reliable, batch-to-batch consistency in strength, corrosion resistance, and formability. This robust quality foundation enables us to flexibly meet the diverse product layout requirements of downstream applications, spanning construction, transportation, solar energy, electronics, and industrial manufacturing sectors.

Extrusion Plant

Jinpeng Aluminum operates a world-class Extrusion Plant equipped with 42 sets of cutting-edge aluminum extrusion production lines, each engineered to deliver exceptional precision, efficiency, and versatility for aluminum profile manufacturing.

Drawing on the internationally renowned design philosophy of Japan’s UBE— a global leader in extrusion technology—our extrusion equipment integrates UBE’s proven engineering principles for optimal melt flow, die longevity, and profile dimensional accuracy. To further guarantee uncompromising performance and reliability, all core components of the extrusion lines (including main squeeze cylinders, hydraulic systems, and control units) are directly imported from Japan. This combination of UBE’s design expertise and authentic Japanese-sourced core parts ensures stable, high-speed extrusion even for complex-profile and high-strength alloy production.

Beyond world-class hardware, Jinpeng Aluminum holds fully independent intellectual property rights (IPRs) for its proprietary quenching system—a critical technology that dictates the mechanical properties of extruded aluminum profiles. Unlike standard quenching processes, our customized system enables precise control over cooling rates and temperature gradients, tailored to the specific metallurgical requirements of different aluminum alloys. This technological edge allows us to perfectly accommodate the production of 1xxx to 7xxx series aluminum alloys, from the highly ductile 1xxx-series pure aluminum to the high-strength 7xxx-series aerospace-grade alloys. Whether the application demands superior corrosion resistance, high tensile strength, or excellent formability, our quenching system ensures each profile meets the exact performance specifications required.

Thanks to the synergy of imported high-performance equipment and proprietary core technologies, the comprehensive technical performance indicators of our extrusion lines rank among the world’s most advanced levels. These include ultra-tight dimensional tolerances (±0.1mm for key profile dimensions), high extrusion efficiency (up to 80% material utilization rate), and consistent batch-to-batch quality. Backed by this robust production setup, our extrusion plant boasts an annual production capacity of 350,000 metric tons, enabling us to fulfill large-volume orders for global clients across construction, solar energy, automotive, and industrial sectors promptly and reliably.

Surface treatment

Powder Coating

Advanced equipment serves as a fundamental prerequisite for manufacturing high-quality products. Kinbon Group is currently equipped with 3 vertical powder coating lines and 1 horizontal powder coating line. These lines are fitted with Switzerland Gema’s original HL-QCC control system and spraying system, supporting the production of products up to 12 meters in length and enabling efficient, fully automated operations.

The group has also introduced an automatic fluorocarbon spraying production line featuring «zero-gap feed-through» technology, paired with Japan Ransburg’s spraying system. This setup accommodates products of any length, facilitating flexible production switching between profiles and sheets. A sophisticated quality control system is implemented throughout the entire process—from spraying to curing—to ensure impeccable product quality.

Anodizing & Electrophoresis

We have introduced automatic production lines for anodizing coloring and electrophoretic coating, with automatic central control technology applied throughout the entire production process. This not only enhances production efficiency but also guarantees consistent product quality. Advanced ion exchange technology is adopted for impurity removal, resulting in products with stable color, uniform film thickness, and excellent corrosion resistance, weatherability, and wear resistance.

Deep processing

Jinpeng Aluminum: Premium Deep Processing for Global Partners

At Jinpeng Aluminum, our deep processing workshop is engineered to turn your design concepts into tangible, high-value aluminum products.

We specialize in:

High-precision CNC Machining: Ultra-tight tolerance control for complex component manufacturing

Advanced Surface Finishing: Corrosion-resistant anodizing, durable powder coating, and aesthetic custom finishes

Superior Friction Stir Welding: Forge-welded, distortion-free joints that elevate structural integrity and durability

Integrated One-stop Service: From extrusion to machining, surface treatment, and final assembly

Strict Quality Compliance: Meeting international standards (ISO 9001/CE/BIS) with 100% pre-shipment inspection

Ideal for architectural, automotive, and industrial applications—Jinpeng’s deep processing capabilities ensure your products stand out in global markets with unmatched precision and reliability.

Quality control

The company has obtained certifications for the ISO 9001 Quality Management System, ISO 14001 Environmental Management System, OHSAS 18001 Occupational Health and Safety Management System, and IATF 16949 International Automotive Industry Standard. Additionally, the certification for DNV-DET NORSKE VERITAS (DNV) is currently in progress. To ensure product excellence, we have deployed a suite of world-class testing equipment for aluminum alloy products, including the Israel ROMIDOT full-dimension scanner, mechanical property testing apparatus, chemical composition analyzers, metallographic microstructure inspection equipment, and non-destructive testing (NDT) instruments.

Warehouse & logistics

Boasting a 50,000-square-meter professional warehousing facility, we implement systematic inventory management for goods destined for clients across global regions. With intelligent cargo positioning systems in place, we ensure rapid and accurate retrieval of required products at all times.

Our warehouse is equipped with 10 standard loading bays, supporting a monthly shipping capacity of 20 full containers and 50 truckloads scale that guarantees timely order fulfillment even for bulk requirements.

Backed by our in-house fleet and a network of vetted logistics partners, we provide secure, end-to-end delivery solutions that cover both domestic distribution and international shipping needs. We are committed to serving as a trusted, reliable supply chain partner for clients worldwide.